1.Alu Honeycomb ceiling introduction

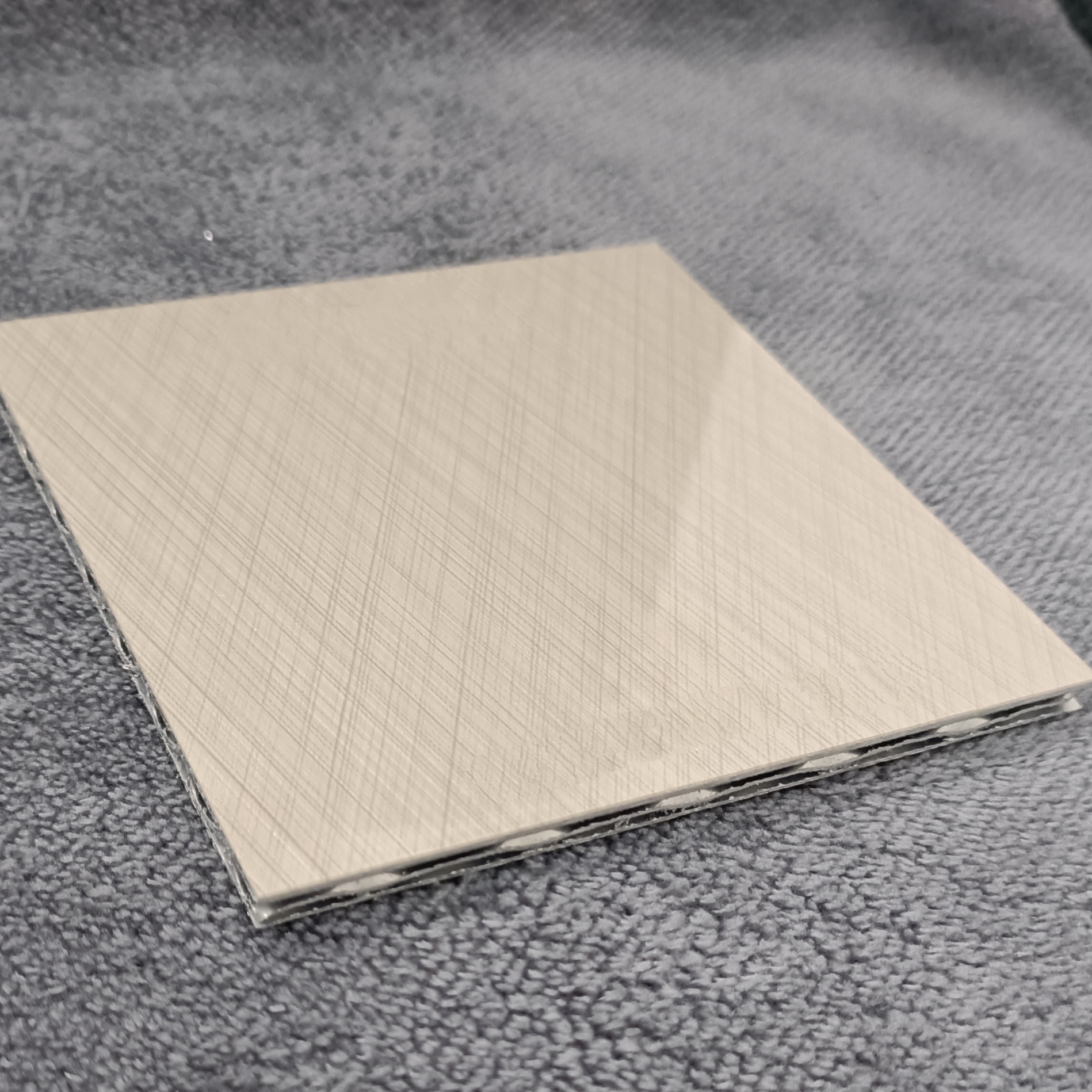

Alu Honeycomb slab is a kind of ceiling material. Product specifications are diverse, the overall decoration is simple and beautiful. Breaking the visual effect of the traditional small square integrated ceiling, it has complete solutions for top space such as thermal insulation and sound insulation, anti-fouling and moisture-proof, and private customization.

Honeycomb slab ceiling is a new type of healthy and environmentally friendly ceiling composed of honeycomb slabs. The size of a single piece is more than 30 times larger than that of traditional small gussets. With the advantages of dust-free and quick installation, personalized customization, simple and advanced, the honeycomb large panel ceiling can quickly replace the traditional small gusset ceiling and gypsum ceiling. Its 6-layer composite, unique honeycomb structure, with a thickness of 7-9mm, is all made of primary aluminum, which has the functions of heat preservation and sound insulation, anti-fouling and moisture-proof. The honeycomb large panel ceiling developed and launched by Relle can be customized according to the needs of customers in terms of size, shape and color. The overall appearance is beautiful, the installation is simple, and the material is stable.

2. Material introduction

Honeycomb aluminum panel is a metal composite panel product series developed in combination with the composite honeycomb panel technology of the aviation industry. The product adopts a "honeycomb sandwich" structure, that is, a composite plate made of high-strength alloy aluminum plate coated with a decorative coating with excellent weather resistance as the surface, bottom plate and aluminum honeycomb core through high temperature and high pressure. This product series has the advantages of excellent material selection, advanced technology and reasonable structure. It not only has excellent performance in large scale and flatness, but also has many choices in terms of shape, surface treatment, color and installation system.

3. Material Features

a. Large board surface, high flatness

Without any reinforcement measures, the size of the honeycomb aluminum panel can reach 1500*5000mm, and it can maintain excellent flatness.

b. Light weight

The weight of the honeycomb aluminum panel is only 5-5.5KG/square meter, which greatly reduces the load-bearing load of the building.

c. High strength

It can withstand high-strength pressure and shear force, is not easy to deform, and can meet the requirements of wind pressure resistance of super high-rise buildings.

d. Customer customization

Honeycomb aluminum panels can be customized according to customer needs in terms of size, shape, paint finish and color.

e. Easy to install

It can be installed in any order, and each wall panel can be disassembled and replaced individually, which improves the flexibility of installation and maintenance and reduces costs.

f. Box structure

The honeycomb aluminum panel is a box-type structure with surrounding edges, which has good airtightness and improves the safety and service life of the honeycomb aluminum panel.

g. Multipurpose

It is suitable for building curtain walls, cladding columns, overhangs, roofs and outdoor ceilings, etc.

3.Product Series

a. Building curtain wall decoration series

The honeycomb aluminum panel wall panel system is based on the composite honeycomb panel technology developed by the aviation industry. Such advanced technology enables the company to manufacture high-strength and light-weight wall panel products. These siding products have very flat surfaces and tightly controlled seam widths, which allow architects to design very straight and beautiful walls with large panels. Except for specific limitations, there is no standard size for honeycomb aluminum panels, and all wall panels are factory-made according to design drawings. This production method allows the panels to be highly flexible in size and shape, such as curved panels and folded panels. This flexibility is widely used in practical applications, as these plates can be installed on almost any joist and are extremely simple to install. The honeycomb aluminum panel system becomes a complete multi-functional and highly competitive wall panel system. It offers these extremely practical solutions for almost all types of wall designs.

b. Ceiling ceiling series

The honeycomb aluminum panel ceiling system provides architects with rich choices from panel material, shape, installation system to color and surface treatment, which can display rich ceiling performance effects and have excellent design freedom. It has an advanced honeycomb aluminum plate production line, which integrates the most advanced ABB inverter and Siemens PLC automatic control system in the United States, and realizes the perfect combination of mechatronics. It is the continuous hot-pressing composite production line with the highest degree of automation in China. Through the perfect process and strict control system, the composite sheet has super peel strength and excellent physical properties, which can be compared with similar brands in the world. The honeycomb aluminum panel is light in weight, good in toughness, high in strength, and good in sound insulation and heat insulation. It is an ideal choice for large-scale project ceilings, and the installation methods of honeycomb aluminum panels are diversified, which can be designed for heavy ceilings and can be repaired by people.

c. Furniture honeycomb panel series

For the modern furniture industry with strict environmental protection requirements, using honeycomb panels as furniture processing materials is a good material choice in the new century. Its completely non-toxic green quality allows furniture manufacturers to process furniture with less In addition, the honeycomb aluminum panel can be diversified such as solid wood, aluminum panel, gypsum board, fireproof board, MDF, natural marble, etc., which can be made into honeycomb panels, and the material selection is convenient.

d. Partition series

The appearance of the honeycomb aluminum panel partition has broken the traditional partition model in the past. With its noble, fresh and stylish style, it has won the market share of medium and high-end office space.

Honeycomb aluminum panel as partition has the following advantages:

(1) Fire protection: aluminum plate is a non-combustible material.

(2) Corrosion resistance: The surface of the honeycomb aluminum plate is treated with epoxy fluorocarbon, which has strong corrosion resistance. No pinholes, cracks, and no bubbles in salt spray for 48 hours.

(3) Environmental protection: The honeycomb panel is a pure aluminum vertical product, does not volatilize any gas harmful to the human body, is non-radioactive and can be completely recycled, and is a 100% environmentally friendly product.

(4) The honeycomb aluminum plate is easy to dismantle and assemble, and the plate will not be dismantled. Due to its light weight and convenient transportation, it can be transported to different places for repeated use. This is unmatched by other partition boards.

e. Elevator engineering series

Honeycomb aluminum panel and marble honeycomb panel have the advantages of fire prevention, heat preservation, sound insulation, shock resistance, heavy strength, buffer resistance and light weight. It can greatly reduce the load of the elevator, and it is the most ideal material for public elevators and freight elevators.

f. Rail transit series

Buses, trains, subways and rail vehicles, commercial transport vehicles and container car bodies, shipbuilding, billboards, interior decoration works, interior partitions and commodity display stands.

g. electronic whiteboard series

Electronic whiteboard: Its back plate material is made of honeycomb aluminum plate. Honeycomb aluminum plate is derived from aerospace materials used in high-end products of civil product technology. . The board surface is durable, the board body is strong and resistant to heavy impact, and the special projection writing film or panel made of high wear-resistant paint is scratch-resistant, high-brightness, high-definition, and easy to clean (can be wiped with a whiteboard cleaner or a damp cloth)

4. Installation advantages

a. The installation structure of the honeycomb large board ceiling is an original paste-top installation. The minimum installation height is 4.5cm, which is less than the height of the gypsum ceiling. Perfectly solve the problems of top piping, wiring, air conditioning, lamps, wall connection and so on.

b. The honeycomb slab ceiling can be used for various shapes of ceilings, such as circular and oval ceilings, heightened secondary beams, and can be used with heating, lighting, central air conditioning and other electrical appliances.

c. The honeycomb large panel ceiling has three optional frames: wide side, narrow side and high side micro-measure, which is easy to use and flexible to install.

d. With a complete set of linear lighting, spotlights, magnetic track lights, to create a fashionable home style without main lights.

You can click this link to get more information: https://www.relleflooring.com/aluminum-honeycomb-ceiling_c36