Classification, installation and maintenance instructions for Relle anti-static floors

Introduce

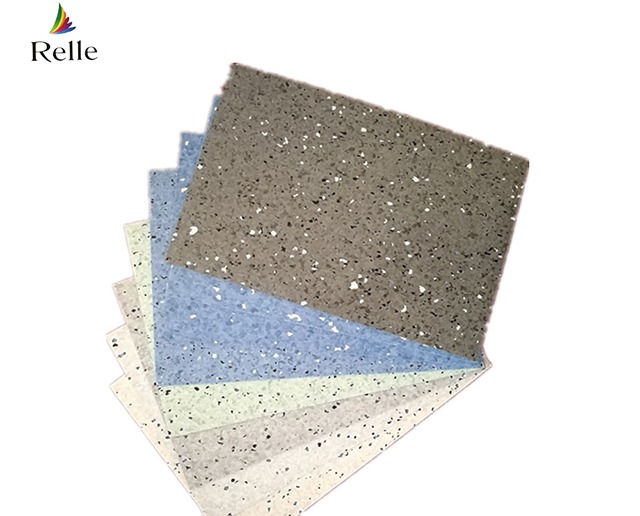

PVC anti-static floor is mainly made of PVC resin and is made by special processing technology. A static-conducting network is formed between the interfaces of PVC particles, which has a permanent anti-static function. It is suitable for places requiring purification and anti-static such as program-controlled computer rooms, computer rooms, and clean workshops in the telecommunications and electronics industries.

The base material is semi-rigid PVC plastic, which has the characteristics of wear resistance, corrosion resistance, no ignition and flame retardant; the conductive material is carbon black with stable performance, and the conductive network runs directly from the upper surface to the lower surface. permanence of performance.

Product category

1. By structure

There are mainly three types of multi-layer composite type, homogenous translucent type and semi-homogenous body type. The so-called multi-layer composite PVC floor means that it has a multi-layer structure, which is generally composed of 4~5 layers of structure. Generally, there are wear-resistant layers (including UV treatment), printing film layers, glass fiber layers, elastic layers Foam layer, base layer, etc. The homogeneous and transparent PVC floor means that it is homogeneous and transparent from top to bottom.

2.According to wear resistance

There are two types: general purpose and durable. The main production and use are general-purpose PVC floors. Some places with very large traffic such as airports, railway stations, etc. need to lay durable PVC floors, which have stronger wear resistance, longer service life and higher prices.

Installation requirements

1.construction surface

The ground should be flat and dry (the surface of the cement floor should be white), without obvious unevenness, and the surface unevenness should be less than 2/1000mm.

2.construction materials

a. anti-static semi-rigid PVC floor;

b. Conductive adhesive, the resistance value should be less than 104Ω;

c. copper foil (or aluminum foil) thickness 0.01-0.05mm width 20-40mm;

d. alcohol, industrial grade;

e. electrode, diameter 2-5mm;

3. construction tools

a. scraper, used for coating conductive adhesive;

b. The rubber throwing head is used to hammer the plastic floor to make it fully bond with the ground;

c. Megohmmeter, voltage 100 volts, used to measure electrical conductivity;

d. Blades for cutting plastic floors;

e. welding gun, used for welding the floor;

f. PVC floor slotting machine, used for slotting the PVC floor welding slot.

Construction Program

1. Clean the ground and find the center line:

First clean the ground slag, then use a tool to find the center of the room, draw the center cross line, and ask the cross line to be divided vertically and equally.

2. Lay copper foil (or aluminum foil) network:

a. Paste the copper foil strips on the ground according to the specified size to form a mesh. The intersections of the copper foils need to be bonded with conductive glue to ensure the conduction between the copper foils;

b. Use a megohmmeter to measure the resistance between adjacent copper foils, and the resistance value should be less than 105Ω. If there is a problem, find the reason and re-paste it to ensure continuity between the copper foils;

c. At least four points per 100 square meters in the pasted copper foil network are connected to the ground wire.

3. Laying the floor:

a. Use a scraper to apply conductive adhesive on part of the ground;

b. When the conductive adhesive feels sticky and non-sticky, start laying the floor. When laying, start from the center position and spread it out to the surrounding area one by one, and tap it with a rubber hammer. Keep a distance of 1.5-2.0mm between the floor and the floor;

c. Continue to apply conductive adhesive with the trowel and cover the floor until the entire floor to be constructed is covered.

d. In the process of laying the floor, it must be ensured that the copper foil passes under the floor

e. Use the welding torch to soften the electrode at high temperature and fill the gap between the floor and the floor.

f. Cut the protruding part of the electrode with an art knife to complete the whole

4. construction surface

g. During the construction process, a megohmmeter is often used to test whether there is continuity between the floor surface and the copper foil. If there is no connection, it is necessary to find out the reason and re-paste it to ensure that the ground resistance of each floor is between 105-108Ω.

h. After the floor is laid, the surface must be cleaned.

Quality of work

A. The ground resistance of the floor surface should be 105-108Ω.

B. There is no bubble on the surface and no shelling phenomenon.

C. After the construction is completed, weld the gap and clean it.

Maintenance

A. When placing items on the floor, avoid dragging heavy objects on the floor, and the contact surface should not be too small. If necessary, use a wooden block liner.

B. When walking on the floor, do not wear shoes with metal nails, let alone scratch and knock on the floor surface with sharp or hard objects.

C. Often use a squeezed wet mop to mop the floor, and the dirty places can be cleaned with solvents such as alcohol.